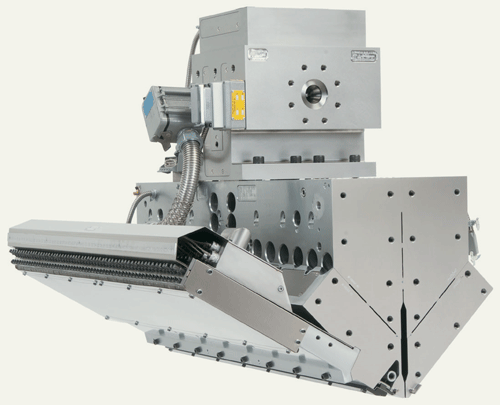

EDI™ BOPP Biax Film Dies

EDI BOPP dies are customizable to meet each processor’s specific requirements. For added layer arrangement versatility, a variety of distribution block systems are available.

Benefits:

- Longer production runs of high quality film are made possible using a variety of high quality materials of construction and surface finishing techniques

- Unsurpassed coextrusion uniformity leading to a consistent thickness across the final film product

- Increase structure versatility with equipment designed to accommodate dissimilar viscosity materials and partial coverage requirements

- Reduce downtime during product changeovers with custom-engineered designs and optional features, based on your specific application needs

- Maximize production efficiency with optimized manifold designs

-

Increase material savings by utilizing the “naked edge” or partial coverage feature, allowing for reduced trim

Features:

- Dedicated flow channels and coextrusion technology allow production capability for 9 or more layers

- Fixed internal deckling makes partial coverage of process dependent film structures possible by allowing for coverage widths to be varied by exchanging internal inserts

- Fixed distribution bar inserts positioned at the point of convergence enable flow geometries to be exchanged without additional machining of die surfaces

-

Optional features include EverSharp™ lip coating technology or laser-hardened lips to increase productivity