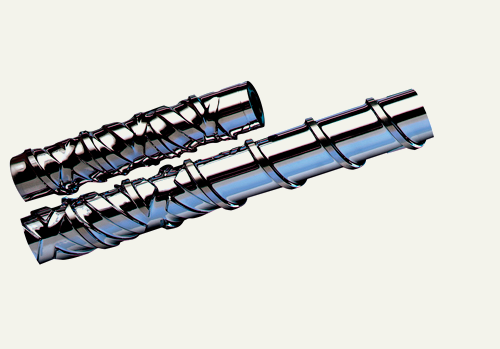

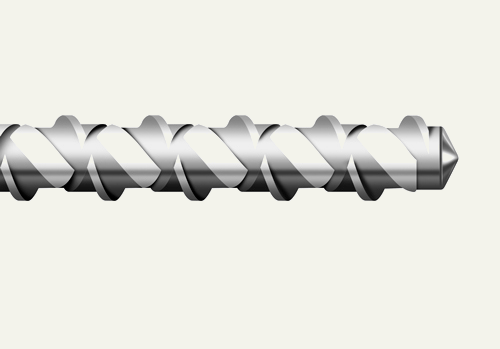

The Nordson XALOY Pulsar® II Mixing Screw offers a combination mixing screw design with good distributive and dispersive qualities. The wave style root geometry provides continually varying, localized high and low pressure areas that yield complete melt homogenization. This screw offers the best low shear mixing design available.

|

Applications:

-

Amorphous and crystalline resins that require superior distribution of additive materials.

-

Direct gas injection foam processes that need uniform bubble size and distribution.

-

Injection applications that demand outstanding melt homogenization with minimal shear to improve part clarity and surface finish.

-

Long glass fiber applications for maximum fiber length retention.

|

Benefits:

-

Wide application and processing window.

-

Optimum part clarity and surface finish.

-

Better physical properties.

-

Superior product performance.

|

|

Advantages:

-

Minimal shear stress.

-

Low fiber breakage.

-

Versatile with all materials.

-

Can be modified to adjust distributive effect.

-

Less back pressure applied.

-

Strong weld lines.

-

Better cell distribution in foam processes.

|

Rating:

When compared to a single stage, general purpose screw with similar root geometry, the Pulsar® II screw delivers a mixing quality 4-5 times better.

|

U.S. patent no. 5,816,698