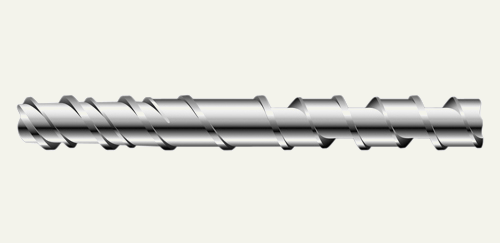

Fusion™ II Screws

The Nordson XALOY® Fusion™ II screw delivers enhanced chaotic mixing while retaining the productivity benefits of faster plastication and lower melt temperature provided by the original Fusion™ screw. Like the original Fusion™ screw, the Fusion™ II has two barrier zones. The first melts and meters the material forward to a homogenizing transition zone. This zone is followed by a second barrier zone with an undulating root profile providing intensive, chaotic mixing. The key difference between the Fusion™ II screw and earlier models is that primary flights in the second barrier zone have grooves. The new design is covered by U.S. patent no. 7,014,353, and has also been applied for international protection throughout the world, in Asia, Europe, and South America.

The grooves in the flights allow materials in adjacent melt channels to mix together, thus enhancing the intensive, chaotic mixing action produced by the screw’s undulating root profile.

This further improves the dispersion of color and additives in the melt and enhances melt homogeneity. The Fusion™ II delivers the same productivity benefits as the earlier design. In injection molding, extrusion and blow molding, the Fusion™ II can deliver increases in plasticating rate of 15 percent and melt temperature reductions of up to 10ºC compared with standard mixing screws.

|

Which Materials?

|

Which Processes?

|

Патент США № 7,014,353

DOWNLOAD