Nordson XALOY Bimetallic barrels meet the needs for wear and corrosion resistance or more than 90% of all injection molding requirements.

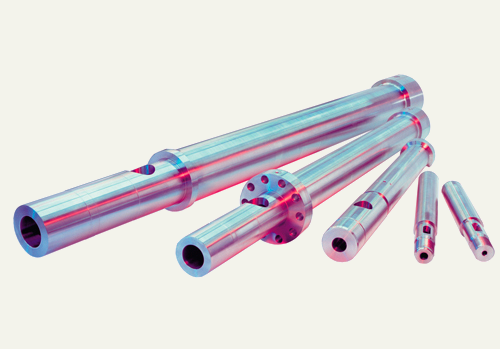

Strong and Straight

The structural shell of Nordson XALOY bimetallic barrels consists of a microalloy steel that maintains high strength and straightness after casting of the wear-resistant alloy lining. Unlike some barrel manufacturers, Nordson XALOY can produce long barrels - up to 240 inches (6.1 meters) - without resorting to butt welding. The benefit to you is a stronger, straighter barrel with no seams to trap polymers that can degrade and contaminate you process.

|

X-800: High wear resistance for injection molding

-

Composition: Tungsten carbide particles uniformly dispersed in a corrosion-resistant nickel alloy matrix.

-

Outstanding resistance to both abrasive wear and corrosion.

-

Essential for molding highly filled abrasive materials such as those containing 25% or more of glass fibers or mineral fillers (calcium carbonate etc.) and hard-to-melt materials such as HMW-HDPE or LLDPE.

-

Resists corrosive attack by aggressive volatiles released by additives or polymers.

X-102: For general purpose use

-

Composition: Nickel-rich iron-boron alloy.

-

Cost-effective choice for either injection molding or extrusion of unfilled or lightly filled polymers having good thermal stability.

-

Outlasts generic competitive barrels in comparative testing.

|

X-220: Higher-chromium iron-boron alloy

-

Premium general-purpose barrel.

-

A step up in resistance to corrosion and abrasive wear

X-306: For highly corrosive environments

-

One of the most corrosion resistant alloys in the industry. A nickel/cobalt base alloy or the most severe corrosive atmospheres.

-

Applications include: highly corrosive environments, acidic salts, material with flame retardants, Teflon, blowing agents, PVDF.

|

|

|