"M-TECS" Magnetic clamping systems

Magnetic clamping plates for different sectors of industry as e.g. for thermoplastics, elastomers, duroplastics, polyurethane, pressure die casting, metal forming and milling applications.

The magnetic clamping systems or clamping plates have been especially designed for injection moulding machines, rubber presses, die casting machines, mould carrier, presses for metal forming and milling machines.

The product range "M-TECS" stands for magnetic clamping technology, that means clamping technology of the highest level and offers the following key advantages for the user:

• standardisation of molds are not required

• height of clamping edge and mold shape are not of importance

• shorter downtimes, lower setup costs

• increased productivity

• clamping in barely accessible positions without any problems

• no reduced clamping surfaces

• process monitoring and thus absolute safety

• clamping force on the complete surface of the mold

• clamping with no deformation of the mold base platen

• reduced maintenance costs

Magnetic clamping plates for different sectors of industry as e.g. for thermoplastics, elastomers, duroplastics, polyurethane, pressure die casting, metal forming and milling applications.

Magnetic clamping plates for different sectors of industry as e.g. for thermoplastics, elastomers, duroplastics, polyurethane, pressure die casting, metal forming and milling applications.

The magnetic clamping systems or clamping plates have been especially designed for injection moulding machines, rubber presses, die casting machines, mould carrier, presses for metal forming and milling machines.

Magnetic clamping plates for different sectors of industry as e.g. for thermoplastics, elastomers, duroplastics, polyurethane, pressure die casting, metal forming and milling applications.

The magnetic clamping systems or clamping plates have been especially designed for injection moulding machines, rubber presses, die casting machines, mould carrier, presses for metal forming and milling machines.

Safety of the magnetic clamping system:

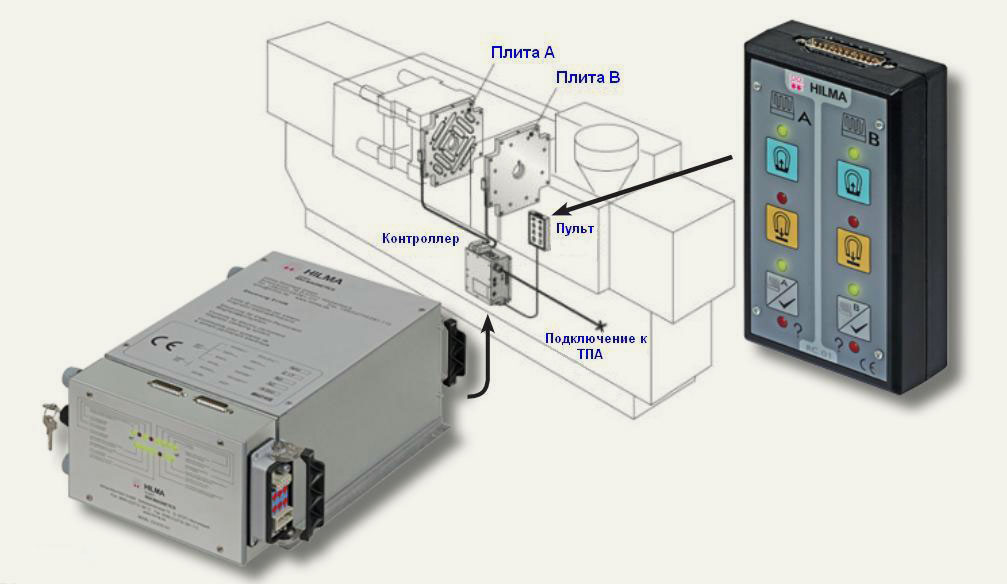

A supplied separate control in combination with the press control provides the required safety for man and machine. During the whole machining process, the control continuously monitors the parameters of the magnetic force, the position of the die (die contact) and the temperature. With the smallest movement of a die half, the machine will be stopped guaranteed safety for man and machine.

An indicator light on the remote control continuously shows the state of the system. The magnetic clamping system is CE tested and complies with the necessary machine directive 98/37/EEC, low voltage directive 73/23 EEC, EMC 89/336.

In addition, all requirements of EN201 for injection moulding machines and EN 289 for presses are met.

All of the desired performance levels can be met.

TÜV inspections at the end customer and with press manufacturers confirm safe handling and use with the ROEMHELD magnetic clamping systems.

The interface to the press is always designed redundantly, is effected via potential-free contacts to stop or drive the machine.

Defined in the standard of EUROMAP70.1 or 70.0, but also customer-specific solutions can be easily realised.

The system M-TECS complies with the following machine directives: 98/37 EEC; 73/23 EEC; EMC 89/336; CE sign

Более подробная информация на сайте www.roemheld.ru.

DOWNLOAD