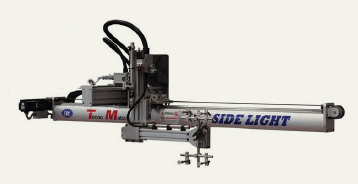

Robots SIDE CNC

The robots to of the series SIDE ENTRY ROBOTS are used as alternative to the robots with traditional structure especially in the following cases:

- when the cycle speed becomes the most important element and therefore mainly in the packaging sector, where the thickness of the pieces are very thin allowing to work with very fast cycles, less than 5 seconds: SIDE FAST CNC;

- when the robot and the injection moulding machine must be insert in “white room” and therefore mainly in the optic sector, medical sector, etc... or when there are problems regarding the height of the ceiling, where the robot with traditional structure, very taller, cannot be employed: SIDE LIGHT CNC;

- in the IML field (in mould labelling) specially in the sector of the food packaging where is necessary that the robot is extremely fast and precise; this kind of robot normally works in symbiosis with other equipments and automations expressly designed and manufactured for the article to produce: SIDE IML CNC.

- management of all the functions by CNC microprocessor,

- high-power brushless servomotors with digital encoder,

- axis with precision runner and prismatic rails with spheres re-circle,

- movement transmission by toothed belt, steel reinforced,

- gears reducers planetary type, with teeth tilted for a greater sturdiness and silence,

- free guided programming (FGP), easily executable also from a non experienced operator using a vast bookstore of

- ‘actions’ ready to the use,

- removable programming console, with great colour display ‘touch screen’, 8.4” size, to introduce the working

- parameters, to monitor the alarms and to use a lot of other functions,

- robot’s wrist with numerous vacuum circuits and other auxiliary circuits,

- self-teaching of the working positions,

- possibility to use, beside the principal program, various types of subroutines that are performed by the robot only when

- certain conditions are verified,

- execution step-step of the working program to a reduced speed to verify its exactness,

- memorization on a Compact Flash of the working parameters of the mould,

- various schemes to stack the pieces,

- speed and acceleration regulation of all the movements,

- piece presence control by vacuum switches or photocells,

- numerous programmable inputs and outputs to interface the robot with external ancillary equipments,

- timing output to drive a conveyor belt,

- possibility to perform whatever sequence of movement desired,

- execution of the movements by linear interpolation,

- possibility to introduce a radius between the movements to reduce the cycle time

DOWNLOAD